PV connectors, as an integral part of solar modules, should be able to be used in harsh, contrast-changing environmental and climatic conditions. Although the environmental climate is different in different regions of the world, the impact of environmental climate on materials and their products can be summed up in four major factors: The first is solar radiation, especially the impact of ultraviolet rays on polymer materials such as plastics and rubber; the second is temperature, among which high and low temperature alternation is a severe test for materials and products; in addition, humidity such as rain, snow, frost, etc. and Effects of other pollutants such as acid rain, ozone, etc. on materials. Furthermore, the connector is required to have high electrical safety protection performance, and the service life must be more than 25 years. Therefore, the performance requirements of photovoltaic connectors are:

1) Safe structure, reliable and easy to use;

2) High environmental and climate resistance indicators;

3) High sealing requirements;

4) High electrical safety performance;

5) High reliability;

In addition to the quality of the pv connector itself, another problem that will cause hidden dangers to the operation of the power station is the cross-mating of the connectors. During the construction of a photovoltaic system, it is often necessary to purchase pv connectors separately to realize the connection of the module strings to the combiner box. This will involve the cross-mating between the purchased connector and the module's own connector. Due to factors such as tolerances, different brands of connectors cannot match well, and the contact resistance is large and unstable, which will seriously affect the safety of the system and power generation efficiency, and it is difficult to obtain manufacturers to take responsibility for quality accidents.

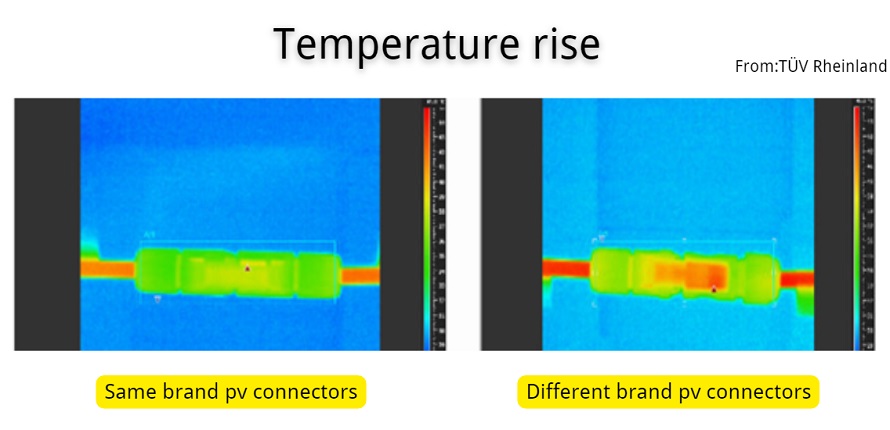

The figure below shows the contact temperature rise and resistance obtained after TUV Rheinland cross-mating different brands of connectors.In the test, different brands of connectors are inserted into each other, and the temperature rise is obviously higher than the allowable temperature range.

For cross-mating of pv connectors for different brands, the IP protection level is more difficult to guarantee. One of the main reasons is that different brands of connectors have different tolerances.

For cross-mating of pv connectors for different brands, the IP protection level is more difficult to guarantee. One of the main reasons is that different brands of connectors have different tolerances.

Even if connectors of different brands can be matched during installation, there will still be traction, torque, and mutual contamination between materials (insulating shells, sealing rings, etc.). This will not meet the standard requirements and will cause problems in the inspection.

Consequences of cross-mating of pv connectors of different brands: loose cables; significantly increased temperature rise leading to fire risks; deformation of connectors leading to changes in airflow and creepage distances, resulting in click hazards.

Obviously, the contact resistance caused by the inter-plugging of different brands of connectors is very unstable, especially its long-term stability is difficult to guarantee, and the heat generation is greater, which may cause a fire in the most severe case of heat generation.

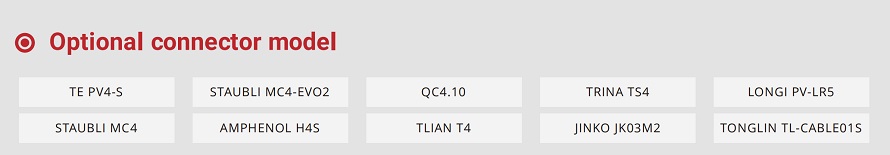

Therefore, In order to provide customers with one-stop purchasing and ensure the safe operation of the plant, generation efficiency and economic benefits. SUNKEAN provides the following connector brands that match the connectors of various mainstream solar panel brands.

For more information about our solar connectors, please contact us: wendy@ske-tech.com, thank you.