I. Introduction

A. Brief overview of the importance of outdoor wiring in today's infrastructure

The importance of outdoor wiring transcends mere convenience. It is the backbone of our technological ecosystem, supporting the delivery of electricity, internet, and telecommunication services that fuel our homes, businesses, and public services. In an age where connectivity and energy needs are escalating, the demands placed on this infrastructure are immense. Outdoor wiring must not only meet current demands but also anticipate future needs, ensuring resilience against environmental challenges and capacity for evolving technological requirements.

Burial cables, specifically designed for underground installation, play a crucial role in this landscape. They protect critical connections from the elements, minimize visual impact, and reduce the risk of damage from natural and human activities. As we delve deeper into the innovations transforming burial cable technology, it becomes clear that the future of outdoor wiring is being redefined. These advancements promise to enhance the efficiency, safety, and sustainability of our infrastructure, ensuring it can support the burgeoning needs of our digital and electrified future.

II. The Evolution of Burial Cable Technology

A. A brief history of outdoor wiring and the advent of burial cables

The story of outdoor wiring begins centuries ago, with early civilizations devising primitive methods of transmitting electrical power over short distances. These early systems, often consisting of bare conductors strung between wooden poles or buildings, were rudimentary but laid the groundwork for the electrified world we inhabit today.

As industrialization swept the globe and electricity became a ubiquitous part of daily life, the demand for more robust and reliable outdoor wiring solutions grew. Above-ground wiring, while effective in many cases, presented numerous challenges, including susceptibility to weather damage, vandalism, and visual intrusion. In response to these challenges, engineers and innovators began exploring alternative methods of outdoor wiring, ultimately leading to the development of burial cables.

The advent of burial cables represented a paradigm shift in outdoor wiring technology. By burying electrical and communication cables directly in the ground, engineers were able to mitigate many of the vulnerabilities associated with above-ground wiring. Early burial cables were often simple affairs, consisting of insulated conductors encased in protective sheaths designed to withstand the rigors of burial.

Over time, advancements in materials science, manufacturing techniques, and insulation technologies led to significant improvements in burial cable design and performance. Modern burial cables boast enhanced durability, resistance to environmental factors, and longevity compared to their predecessors, making them the go-to choice for outdoor wiring applications where reliability is paramount.

B. Early challenges with burial cables (material degradation, water ingress, etc.)

Material Degradation: Early burial cables often suffered from degradation of their insulation and sheathing materials over time. Exposure to moisture, temperature fluctuations, and environmental contaminants could cause the materials to become brittle, leading to cracking, flaking, and loss of integrity.

Water Ingress: Even with protective sheathing, moisture could still penetrate the cable's insulation over time, leading to electrical shorts, corrosion of conductors, and degradation of performance. In regions with high levels of groundwater or frequent rainfall, water ingress posed a significant threat to the reliability and longevity of buried cable installations.

Mechanical Damage: The mechanical integrity of burial cables was also a concern, particularly during installation and maintenance activities. Poorly designed or inadequately protected cables were susceptible to damage from excavation equipment, landscaping activities, and accidental impacts. Without proper reinforcement and shielding, burial cables were vulnerable to cuts, abrasions, and punctures, which could compromise their electrical insulation and structural integrity.

Environmental Compatibility: Early burial cables often lacked adequate protection against environmental factors such as UV radiation, chemical exposure, and soil erosion. These environmental stressors could accelerate material degradation, reduce cable lifespan, and compromise electrical performance.

III. Current Innovations in Burial Cable Technology

A. Enhanced Material Durability

Advanced Insulation Materials: Modern burial cables often utilize advanced insulation materials that offer superior resistance to moisture, temperature extremes, and mechanical stress. High-density polyethylene (HDPE), cross-linked polyethylene (XLPE), and ethylene propylene rubber (EPR) are among the commonly used materials known for their exceptional durability and electrical properties. These materials provide a robust barrier against water ingress, UV radiation, and chemical exposure, ensuring long-term reliability in underground environments.

Corrosion-Resistant Sheathing: In addition to improved insulation, burial cables feature corrosion-resistant sheathing materials that protect against environmental contaminants and aggressive soils. Polyvinyl chloride (PVC), polyethylene (PE), and thermoplastic elastomers (TPE) are examples of sheathing materials engineered to withstand chemical exposure and mechanical abrasion. By effectively shielding the cable's conductors and insulation layers, these materials enhance overall durability and resistance to degradation over time.

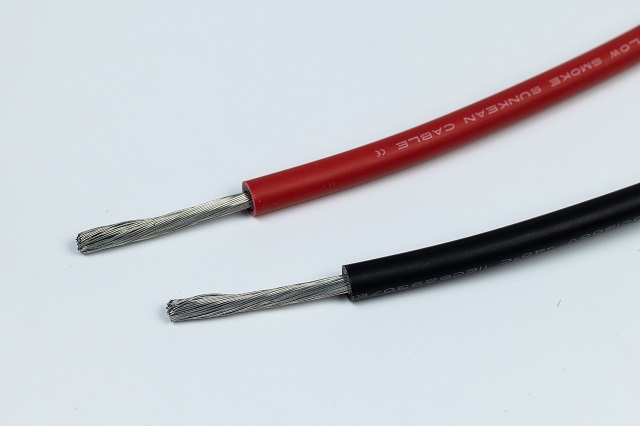

Reinforced Structural Design: Modern burial cables often incorporate reinforced structural designs to enhance mechanical strength and resilience. Embedded armor layers, strength members, and protective jackets are strategically integrated into the cable's construction to resist crushing, bending, and impact forces during installation and operation. These reinforcements not only safeguard the cable's internal components but also ensure reliable performance in challenging underground conditions. Like SUNKEAN's armored series of cables (e.g. TÜV 2PfG 2642 PV1500DC-AL DB), the armor layer makes it rodent and ant resistant.

Environmental Compatibility Considerations: Innovations in burial cable technology also encompass considerations for environmental compatibility, ensuring that cables are well-suited for a wide range of soil types, climates, and application scenarios. Cable manufacturers conduct rigorous testing and analysis to assess the long-term performance of materials in various environmental conditions, allowing them to optimize cable designs for maximum durability and reliability.

Resilience to Extreme Conditions: Burial cables are designed to withstand extreme conditions, including temperature fluctuations, seismic activity, and soil movement. By incorporating materials with high thermal stability, low coefficient of thermal expansion, and excellent mechanical properties, modern burial cables can maintain performance integrity even in the most demanding environments. This resilience ensures continuous operation and minimizes the risk of service disruptions due to environmental factors.

B. Smart Monitoring Capabilities

Embedded Sensor Technology: At the heart of smart burial cables are embedded sensors capable of measuring a wide range of operational parameters, including temperature, moisture levels, electrical current, and insulation integrity. These sensors provide real-time data on the cable's condition, enabling proactive maintenance and early detection of potential issues before they escalate into serious problems. The use of fiber optic sensors, in particular, has gained prominence for their sensitivity and ability to monitor long cable lengths comprehensively.

Remote Monitoring and Diagnostics: Coupled with embedded sensors, remote monitoring systems allow for the continuous observation of burial cable conditions from centralized control centers or mobile devices. This capability ensures that operators can quickly identify and respond to anomalies, such as moisture ingress or insulation breakdown, minimizing downtime and extending the lifespan of the cable infrastructure. Diagnostic tools integrated with these systems can also help pinpoint the location of faults, simplifying repair and maintenance efforts.

Predictive Maintenance Algorithms: Leveraging the power of big data analytics and machine learning, smart burial cables can predict potential failures and recommend maintenance activities before issues arise. Predictive maintenance algorithms analyze historical and real-time data to identify patterns and anomalies that precede common cable faults. This proactive approach to maintenance can significantly reduce the incidence of unexpected failures, optimize maintenance schedules, and lower operational costs.

C. Eco-friendly Developments

Biodegradable Materials: A groundbreaking advancement in burial cable technology is the use of biodegradable materials for insulation and sheathing. These materials are designed to decompose naturally over time once they've served their purpose, significantly reducing the environmental footprint left by discarded cables. Unlike traditional plastics and polymers that can linger in the environment for centuries, biodegradable alternatives offer a path towards a more sustainable cable infrastructure.

Recycled and Recyclable Materials: The incorporation of recycled materials into burial cable production is another step towards sustainability. Many manufacturers have started using recycled plastics and metals for the non-conductive components of cables, such as the outer sheathing and armor. Furthermore, designing cables to be recyclable at the end of their lifecycle ensures that the materials can be repurposed, reducing the need for virgin resources and minimizing waste.

IV. The Impact of Innovations on Installation and Maintenance

A. Simplified Installation Processes

Pre-Connectorized Systems: Pre-connectorized cable systems come equipped with factory-installed connectors, eliminating the need for on-site splicing and terminations. This innovation significantly speeds up the installation process by reducing the steps required to deploy burial cables. Technicians can lay down lengths of cable and connect them to equipment or junctions without specialized tools or skills, which is especially beneficial in harsh or difficult-to-access environments. The precision and reliability of factory-made connections also enhance the overall quality and performance of the installation, reducing the likelihood of errors and rework. SUNKEAN is committed to providing this one-stop energy connectivity solution, and as the largest distributor of Amphenol in China for the East China region, we are able to provide the best possible service to our customers.

Modular Cable Systems: Modular cable systems offer unparalleled flexibility and scalability, allowing for easy expansion and reconfiguration of networks as demands change. These systems consist of segments that can be quickly connected or rearranged, supporting a plug-and-play approach to outdoor wiring. For installers, this means reduced labor time and the ability to adapt to unforeseen challenges without significant modifications to the initial design. Modular systems also facilitate easier maintenance and upgrades, as individual segments can be replaced or augmented without disrupting the entire network.

B. Enhanced Longevity and Reduced Maintenance

Enhanced Protective Measures: Modern burial cables often incorporate enhanced protective measures, such as improved water blocking and anti-rodent features, to safeguard against common causes of damage. These measures not only extend the cables' operational life but also lessen the likelihood of maintenance being required due to environmental or biological factors. The combination of physical and chemical protections ensures that the cables can withstand harsh conditions for longer periods.

V. Future Trends and Predictions in Burial Cable Technology

Nanotechnology and Cable Materials: The integration of nanotechnology into cable materials is poised to revolutionize burial cable construction. Nanomaterials can offer unprecedented strength, flexibility, and conductivity, potentially reducing cable size while enhancing performance and durability. This could lead to lighter, more efficient cables that require less raw material to manufacture and are easier to install, significantly lowering their environmental impact.

Wireless Sensor Networks for Enhanced Monitoring: Advancements in wireless sensor networks are expected to elevate smart monitoring capabilities to new heights. These sensors, embedded within cable systems, could continuously transmit data on cable health, environmental conditions, and even detect physical damage in real-time. Such precise monitoring would enable immediate maintenance responses, further reducing downtime and extending cable lifespan.

Autonomous Repair Systems: Looking further ahead, the concept of self-healing materials could be applied to burial cables. Imagine cables that can autonomously repair minor cuts or abrasions, preserving the integrity of the infrastructure without human intervention. This technology, while still in its infancy, holds the promise of drastically reducing maintenance costs and enhancing network reliability.

Increased Focus on Eco-friendly Solutions: As global emphasis on sustainability intensifies, future burial cable technology will likely continue to evolve towards even greener solutions. This could include the development of fully recyclable or biodegradable cables, the use of eco-friendly manufacturing processes that minimize carbon footprints, and the implementation of lifecycle management practices that ensure minimal environmental impact from production to disposal.

Enhanced Connectivity with IoT Integration: The Internet of Things (IoT) is set to become increasingly intertwined with burial cable technology, facilitating smarter, more interconnected infrastructures. Cables could not only transmit data but also gather it, integrating with a wide array of sensors and devices to support smart cities, autonomous vehicles, and other IoT applications. This integration promises to unlock new levels of efficiency, safety, and functionality in various sectors.

Modular and Scalable Network Designs: The trend towards modular and scalable network designs is expected to accelerate, enabling infrastructure to adapt more fluidly to changing needs. Future burial cables might come in standardized, easily configurable segments that can be quickly assembled, reconfigured, or expanded, reducing installation and upgrade times and making networks more versatile than ever before.

VI. Conclusion

If you are interested in high-quality burial cables like UL4703, H1Z2Z2K / 62930 IEC, RPVU, AL DB 2PfG 2642, and comprehensive after-sales service, welcome to visit SUNKEAN, where there are all kinds of latest cable products you need. If you have any needs, you can leave a message to our salesman, thank you for your coordination. Email: sales@sunkean.com