I. Introduction

Crimping is a technique in which the metal is compressed and displaced within specified limits and the wire is connected to the terminal through a tool or equipment using a compressive force. At its core, cable crimping is the process of joining two electrical conductors using a connector and a crimping tool. This method secures the wires within the connector, establishing a reliable and conductive pathway for electricity to flow. Just as a building relies on a solid foundation for stability, the efficiency and safety of electrical systems heavily rely on the quality of their crimped connections.

II. Importance of cable crimping in various applications

A. Industrial Machinery:

In the realm of industrial machinery, where efficiency and productivity are paramount, secure connections are the linchpin. Machines operating in manufacturing plants, assembly lines, and processing facilities rely on an intricate web of electrical connections to function seamlessly. Any weak link in this network can result in costly downtime, production delays, or even equipment damage.

B. Renewable Energy Systems:

The shift toward renewable energy sources, such as solar and wind power, hinges upon reliable connections for efficient energy harvesting and distribution. Within solar farms or wind turbines, connections are not just pathways; they're the conduits for harnessing clean energy. A single unreliable connection can lead to energy loss, decreased efficiency, and operational inefficacies, impacting the viability of these sustainable energy sources.

C. Automotive:

Consider the vast network of wires and connectors coursing through modern vehicles, orchestrating everything from engine management to entertainment systems. Reliable crimps are indispensable in ensuring these systems operate seamlessly, withstanding the rigors of vibrations, temperature variations, and constant movement.

III. The Effect of Excellent Quality of Cables on Cable Crimping

The quality of cables utilized in the crimping process is an essential factor that significantly influences the efficacy and reliability of crimped connections.

A. Consistency in Performance:

High-quality cables are manufactured to rigorous standards, ensuring uniformity in conductor size, insulation thickness, and material quality.

B. Durability and Resilience:

Superior materials used in excellent quality cables have durability and resilience to environmental stressors. Whether it's exposure to extreme temperatures, moisture, or mechanical strain, high-quality cables withstand challenges, preserving the integrity of crimped connections over time.

C. Optimal Electrical Conductivity:

Excellent quality cables feature high-grade conductors that facilitate electrical conductivity. This conductivity can reduce the risk of voltage drops, signal loss, or overheating with lower-quality cables.

D. Compatibility with Connectors:

Excellent quality cables are engineered to seamlessly integrate with connectors designed for specific wire gauges and types. This compatibility ensures a snug fit, contributing to predictability in the crimping process and enabling technicians to achieve precise crimps that securely join the conductor within the connector.

IV. Factors Influencing Quality in Cable Crimping

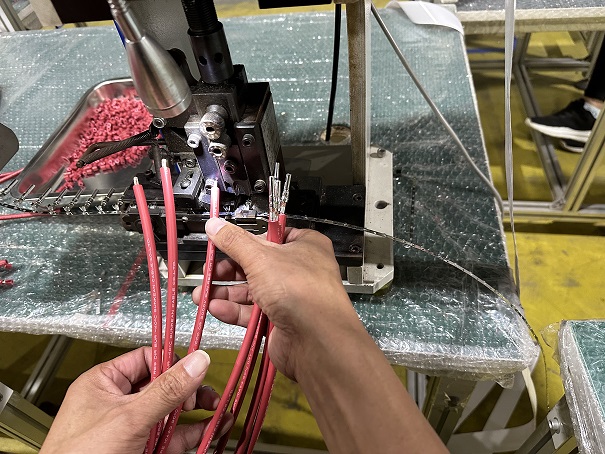

A. Precision Tools and Equipment:

Quality cable crimping heavily relies on the utilization of precise and appropriate tools. The crimping process demands tools specifically designed to exert controlled pressure, ensuring the perfect compression and secure bonding of wires within connectors. Investing in quality crimping tools is an investment in the integrity of the entire electrical system. Not only does SUNKEAN have a full range of crimping equipment, but the laboratory is also equipped with a professional terminal profile analyzer, which is capable of obtaining important information such as the degree of compression of the conductor strands, curling of crimped sides, and damage to the crimped area of the conductor, to provide optimal quality control of crimped connections.

B. Quality of Materials:

High-quality cables, terminals, and connectors form the foundation for reliable connections. Inferior materials compromise the effectiveness of crimping, leading to increased resistance, signal loss, or susceptibility to environmental factors.

C. Training and Expertise:

Beyond tools and materials, the workers play a pivotal role in ensuring quality cable crimping, skilled technicians trained in the nuances of crimping techniques are indispensable. Their expertise ensures the crimping process is executed meticulously, adhering to industry standards and best practices. From understanding proper wire preparation to applying the correct pressure during crimping, these technicians are the linchpin in guaranteeing consistently high-quality connections.

V. Advantages of Quality Cable Crimping

A. Reliable Connections:

High-quality cable crimping ensures that the wires are precisely secured within the connector, creating a solid point of contact. This precise contact minimizes resistance and interference, resulting in efficient power flow without signal loss or attenuation and maintaining stable conductivity.

B. Service Life:

They are highly resistant to temperature fluctuations, vibration, moisture, and mechanical stress, ensuring longevity and functionality even under harsh conditions. This durability translates into sustained performance, reducing maintenance requirements and increasing the overall reliability of the electrical system.

C. Safety Considerations:

In addition to functionality, high-quality cable crimping greatly enhances safety. A strong crimp minimizes the risk of short circuits, overheating, or electrical failures, thereby avoiding accidents or potential hazards. In industrial environments, homes, or any environment where electrical systems operate, the reliability of crimped connections is critical to preventing safety hazards and protecting people and property from potential electrical accidents.

VI. Conclusion

Currently, the crimping process is considered to be better than the welding process, the crimping process is characterized by the absence of solder and flux, and you can get a reliable connection, which overcomes the welding technology solder cleaning difficulties and welding surface oxidation and other shortcomings. The operation of the crimping process has small environmental requirements, simple operation, and a low human-caused failure rate.

SUNKEAN has mastered the crimping process after many years of precipitation and has passed the terminal cross-section analysis, pulling force test, resistance test, and other heavy tests to ensure the perfect quality of cables at the time of shipment.

In the future, SUNKEAN will continue to focus on the fields of photovoltaic, energy storage, and charging, further consolidate the core products and technology foundation, continuously promote technological innovation, optimize product performance, improve product quality, deepen the layout of the wire and cable market, help dual-carbon policy, and empower the photovoltaic and energy storage industries. At the same time, SUNKEAN will, as always, escort the needs of customers, guarantee product quality with professional, thorough, rigorous, and efficient comprehensive services, and put into practice the concept of "customer-centered" to make SUNKEAN quality deeply rooted in people's hearts.