As the world shifts toward low-carbon, renewable energy solutions, it is no longer enough for solar power systems to merely generate clean electricity. The materials and technologies used within those systems must also embody the principles of sustainability, safety, and environmental responsibility. In this context, irradiation cross-linking technology used in solar cables and PV cables represents a major leap forward.

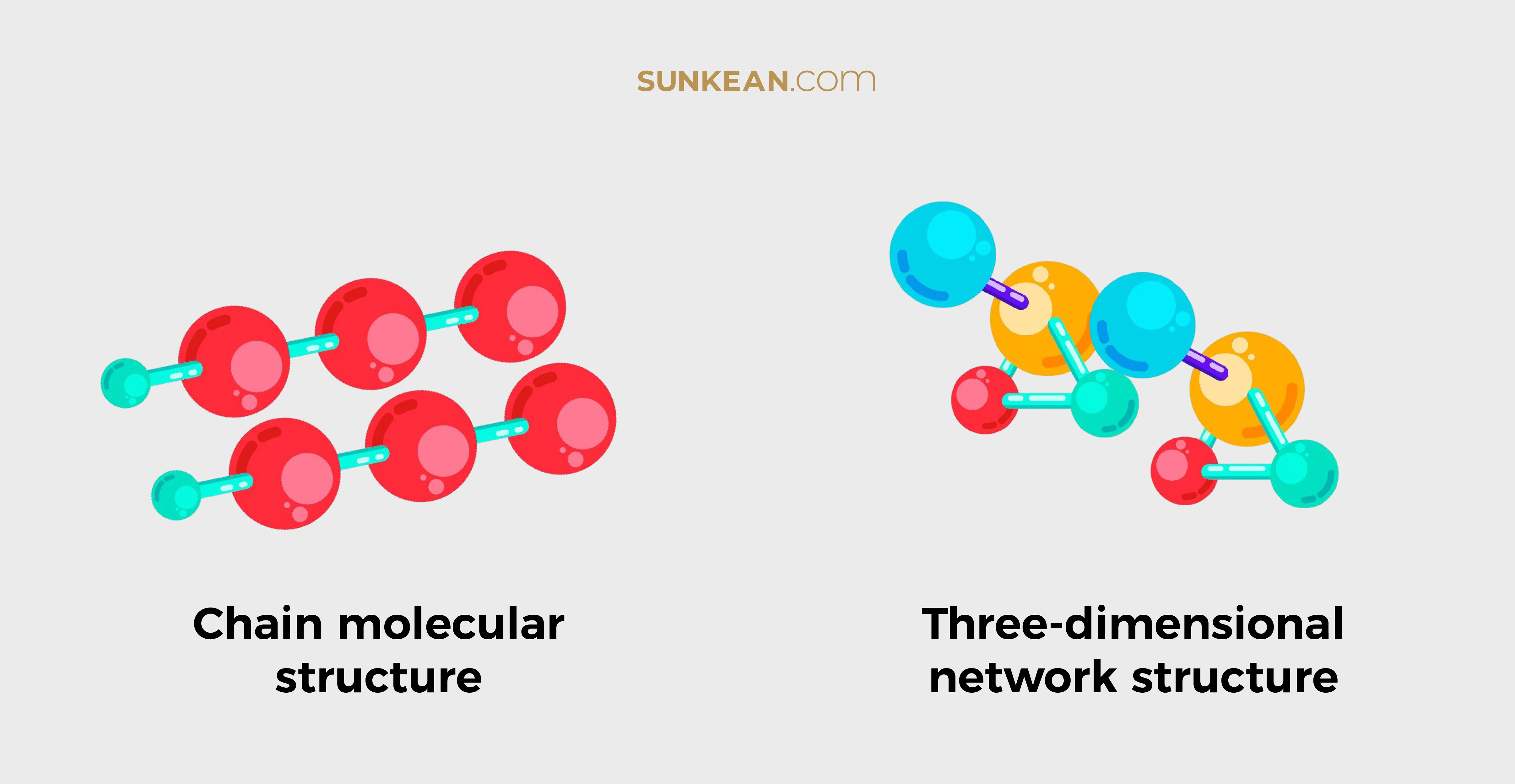

Traditional cross-linking methods for cable insulation typically rely on chemical agents, such as peroxides or silane compounds, which initiate polymer bonding through heat and pressure. While effective, these chemical agents can:

· Release volatile organic compounds (VOCs) during processing

· Leave behind residual chemicals that may degrade over time

· Require additional manufacturing steps for curing, which increases energy use and operational complexity

In contrast, irradiation cross-linking is a non-chemical, low-emission alternative. It uses electron beam technology to directly modify the molecular structure of insulation materials without introducing any additives. This results in:

· No chemical residue in the final product

· No curing ovens, which saves energy and reduces carbon emissions

· No off-gassing, creating a safer and cleaner working environment in the manufacturing process

This not only aligns with the principles of green manufacturing but also supports stricter environmental compliance and ESG (Environmental, Social, and Governance) standards increasingly demanded by global markets and regulators.