Reinforced Structural Design: Modern burial cables often incorporate reinforced structural designs to enhance mechanical strength and resilience. Embedded armor layers, strength members, and protective jackets are strategically integrated into the cable's construction to resist crushing, bending, and impact forces during installation and operation. These reinforcements not only safeguard the cable's internal components but also ensure reliable performance in challenging underground conditions.

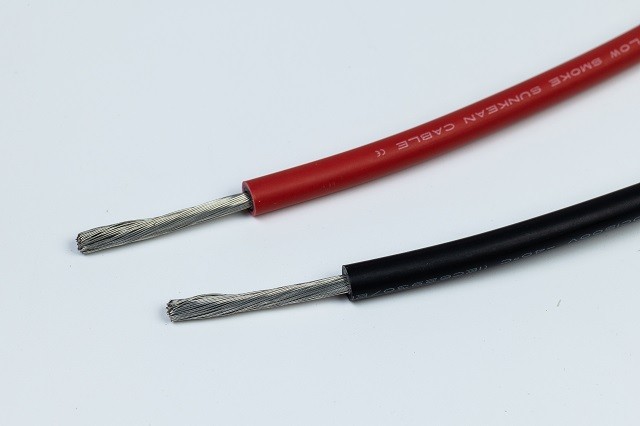

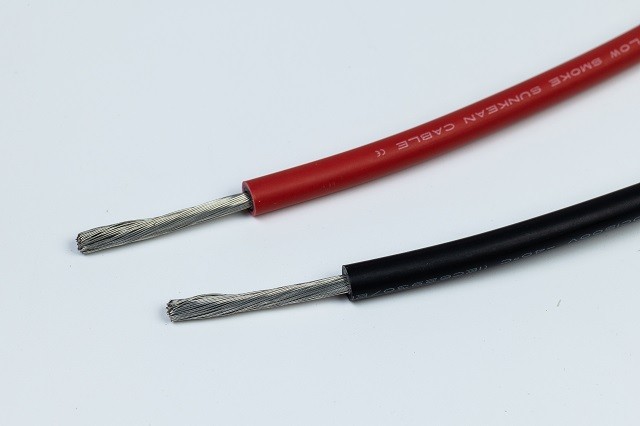

Like SUNKEAN's armored series of cables (e.g. TÜV 2PfG 2642 PV1500DC-AL DB), the armor layer makes it rodent and ant resistant.Environmental Compatibility Considerations: Innovations in burial cable technology also encompass considerations for environmental compatibility, ensuring that cables are well-suited for a wide range of soil types, climates, and application scenarios. Cable manufacturers conduct rigorous testing and analysis to assess the long-term performance of materials in various environmental conditions, allowing them to optimize cable designs for maximum durability and reliability.

Resilience to Extreme Conditions: Burial cables are designed to withstand extreme conditions, including temperature fluctuations, seismic activity, and soil movement. By incorporating materials with high thermal stability, low coefficient of thermal expansion, and excellent mechanical properties, modern burial cables can maintain performance integrity even in the most demanding environments. This resilience ensures continuous operation and minimizes the risk of service disruptions due to environmental factors.

B. Smart Monitoring Capabilities

Embedded Sensor Technology: At the heart of smart burial cables are embedded sensors capable of measuring a wide range of operational parameters, including temperature, moisture levels, electrical current, and insulation integrity. These sensors provide real-time data on the cable's condition, enabling proactive maintenance and early detection of potential issues before they escalate into serious problems. The use of fiber optic sensors, in particular, has gained prominence for their sensitivity and ability to monitor long cable lengths comprehensively.

Remote Monitoring and Diagnostics: Coupled with embedded sensors, remote monitoring systems allow for the continuous observation of burial cable conditions from centralized control centers or mobile devices. This capability ensures that operators can quickly identify and respond to anomalies, such as moisture ingress or insulation breakdown, minimizing downtime and extending the lifespan of the cable infrastructure. Diagnostic tools integrated with these systems can also help pinpoint the location of faults, simplifying repair and maintenance efforts.

Predictive Maintenance Algorithms: Leveraging the power of big data analytics and machine learning, smart burial cables can predict potential failures and recommend maintenance activities before issues arise. Predictive maintenance algorithms analyze historical and real-time data to identify patterns and anomalies that precede common cable faults. This proactive approach to maintenance can significantly reduce the incidence of unexpected failures, optimize maintenance schedules, and lower operational costs.

C. Eco-friendly Developments

Biodegradable Materials: A groundbreaking advancement in burial cable technology is the use of biodegradable materials for insulation and sheathing. These materials are designed to decompose naturally over time once they've served their purpose, significantly reducing the environmental footprint left by discarded cables. Unlike traditional plastics and polymers that can linger in the environment for centuries, biodegradable alternatives offer a path towards a more sustainable cable infrastructure.

Recycled and Recyclable Materials: The incorporation of recycled materials into burial cable production is another step towards sustainability. Many manufacturers have started using recycled plastics and metals for the non-conductive components of cables, such as the outer sheathing and armor. Furthermore, designing cables to be recyclable at the end of their lifecycle ensures that the materials can be repurposed, reducing the need for virgin resources and minimizing waste.