Because PV cables are often used outdoors, underground, or even underwater, there is a trade-off between fire and water resistance when selecting cables.

a. Cables used between PV modules and inverters

Environmental conditions: These cables are often installed in open-air environments, such as rooftop solar systems, ground-mounted PV arrays, or large solar farms. While exposure to moisture, rain, and sunlight is common, the risk of immersion in water is minimal. However, due to the presence of electrical connections and high operating currents, the risk of fire is more of a concern.

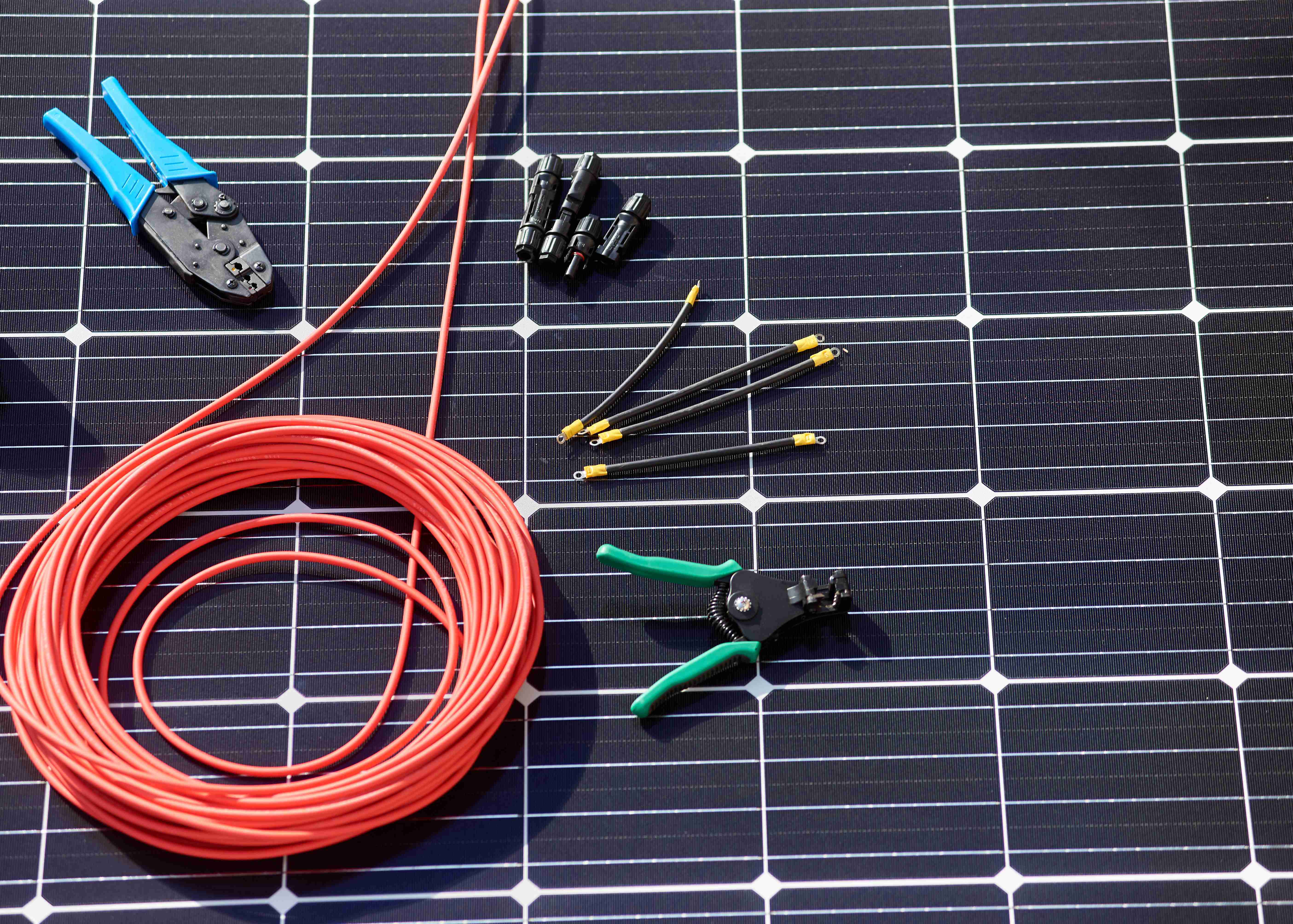

Recommended cable selection: CCA-rated flame-retardant PV cables. The outer sheath of these cables should be made of low-smoke, halogen-free flame-retardant materials to minimize toxic emissions in the event of a fire.

Additional protection measures: Ensure correct cable routing and spacing to prevent overheating; install fire-resistant conduits or protective trays in areas with higher fire risks (such as near inverters or junction boxes); use UV-resistant sheaths to prevent long-term degradation caused by sunlight exposure.

b. DC cables installed underground or underwater

Environmental conditions: In large solar farms, DC cables are often buried underground to protect them from physical damage and environmental exposure.

Floating solar farms or offshore PV systems require cables with long-term immersion resistance because they may be installed on the water surface or in areas prone to flooding. Water infiltration is the biggest problem because it can cause insulation damage, short circuits and accelerated cable aging. The risk of fire is generally lower compared to above-ground installations, but it must still be considered in high-power applications.

Recommended cable selection: AD8-rated waterproof PV cable. AD8 cables use special water-blocking insulation materials such as high-density cross-linked polyethylene (XLPE). The conductors should be tinned copper to prevent oxidation and corrosion caused by long-term exposure to water. The outer sheath should have a strong resistance to water diffusion, ensuring that even tiny amounts of moisture cannot penetrate the insulation.

Additional protection measures: For increased fire safety, fire-resistant cable trough boxes can be installed in underground cable trenches. In the event of an electrical fault, these enclosures help control the flame; double-layer jacket design can be achieved, with a waterproof inner layer and a flame-retardant outer layer to achieve a balance between fire protection and waterproofing; waterproof cable joints and junction boxes are used to prevent moisture intrusion at the connection points.