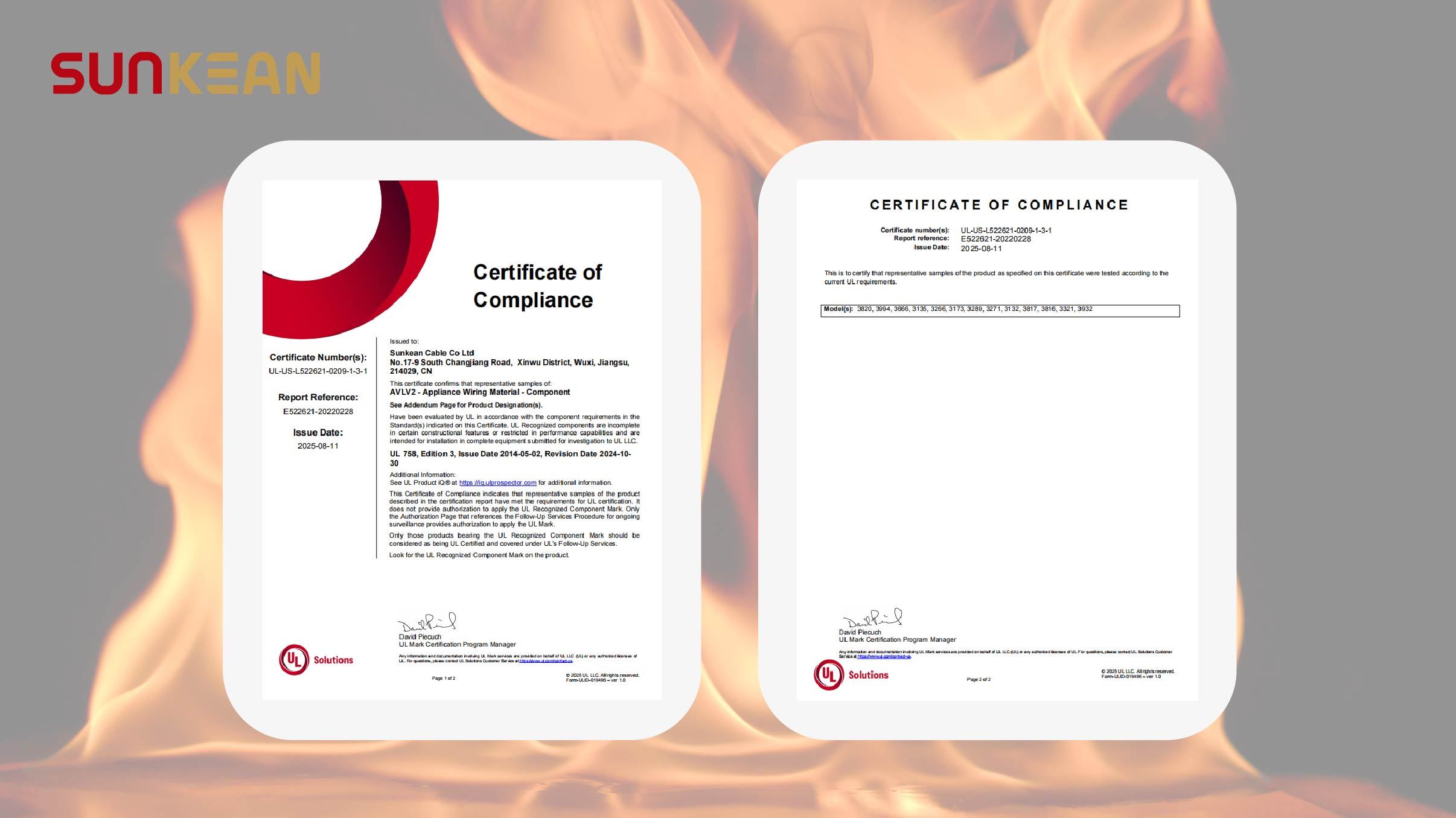

Q1: What is UL758 certification, and why is it important for appliance wiring materials (AWM)?

A: UL758 is a safety standard developed by Underwriters Laboratories specifically for Appliance Wiring Materials (AWM). For exporters and manufacturers, UL758 certification is widely recognized in North America and other international markets and is often a mandatory requirement for product compliance and market access.

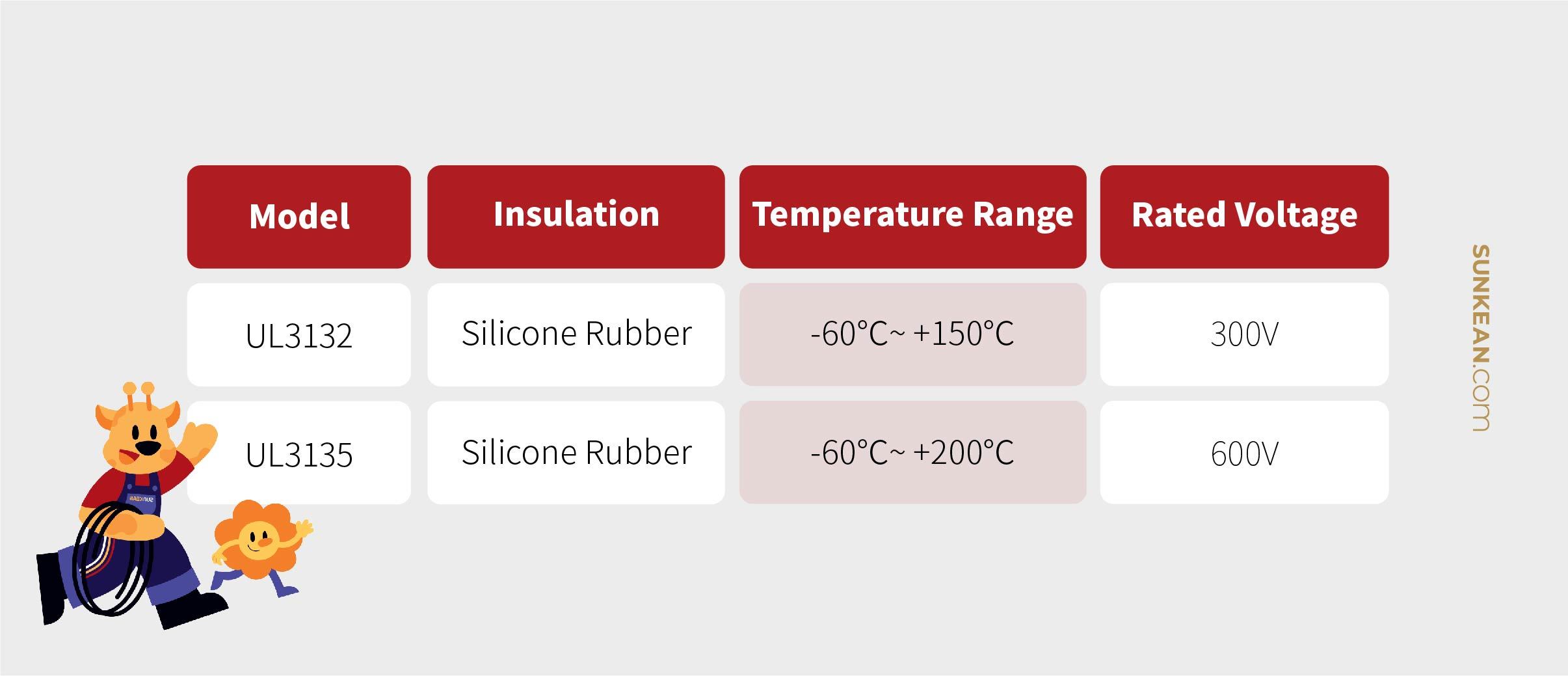

Q2: Why is silicone rubber chosen as the insulation material for high-temperature cables?

A: Silicone rubber offers a unique combination of thermal stability, flexibility, and environmental resistance. Its molecular structure (with silicon-oxygen bonds) provides exceptional performance across an extreme temperature range (-60°C to +200°C).

Q3: Are SUNKEAN's UL3132 and UL3135 cables suitable for outdoor and harsh environments?

A: Absolutely. These cables are engineered to perform reliably in challenging conditions. They offer UV resistance, protection against moisture and corrosion, and high tolerance to temperature fluctuations. With additional resistance to oils and chemicals, as well as compliance with the VW-1 flame retardancy standard.

Q4: Can these cables be used in tight spaces or with frequent bending?

A: Yes. The inherent flexibility of silicone rubber allows for a small bending radius, making these cables easier to install in confined spaces like control cabinets, inverter housings, or battery compartments. Their ability to withstand repeated flexing without cracking or performance degradation reduces installation difficulty and extends service life.

Q5: Where can SUNKEAN UL758-certified cables be typically applied?

A: They are commonly used in: Renewable energy systems, Industrial automation and motor drives, Power distribution and control cabinets, High-temperature appliances and HVAC systems, Automotive and transport electrical systems, Outdoor and harsh environment applications.

Q7: Does SUNKEAN provide custom cable length or specification options?

A: Yes, SUNKEAN offers customized solutions tailored to specific voltage, temperature, size, and certification requirements. Feel free to contact our technical team with your project details for more information. Email: sales@sunkean.com