Connecting an intelligent and sustainable future

For Aluminum Alloy Cable Connection

Provide Efficient Installation

Advantages for SUNKEAN Aluminum Cable

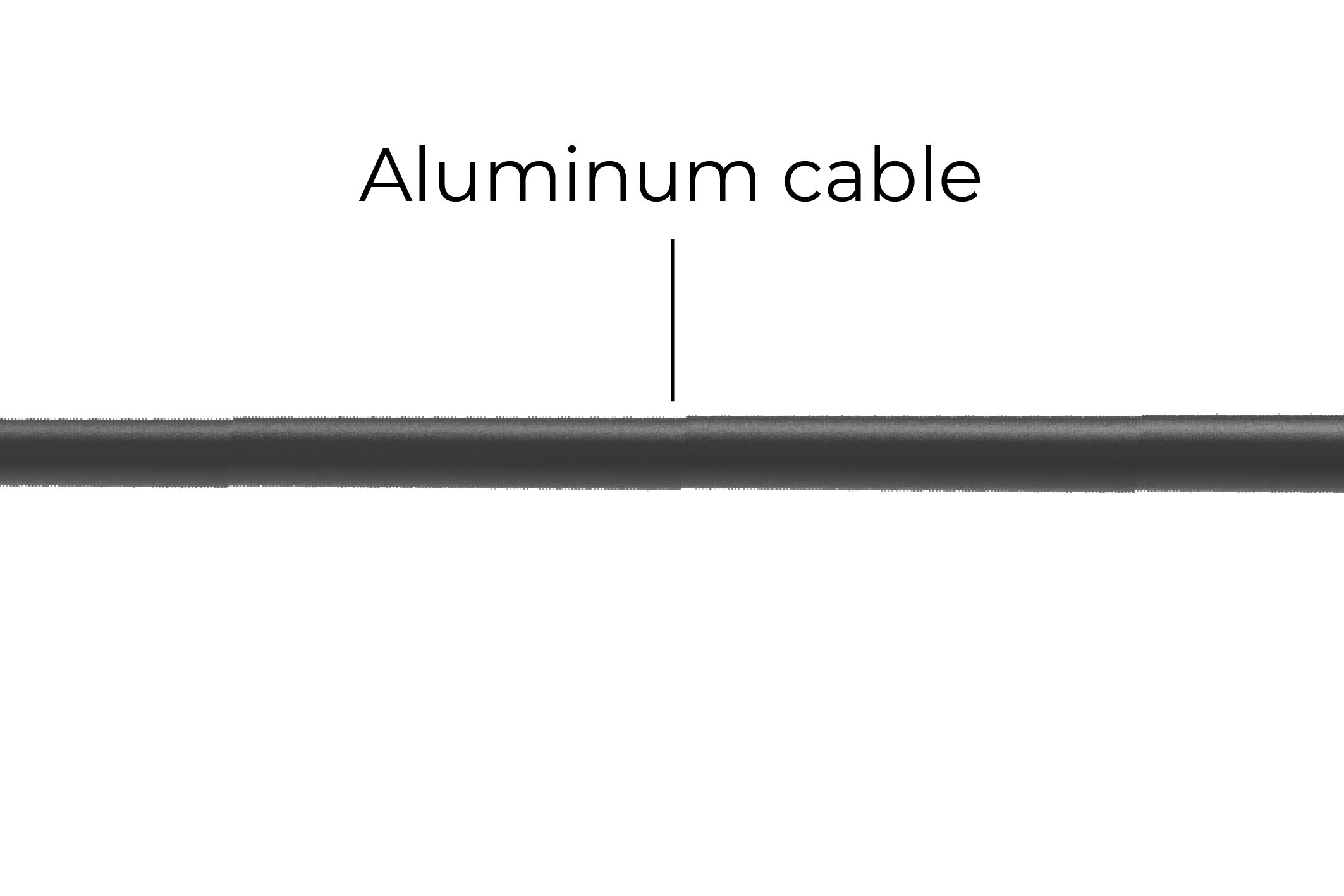

Aluminum Alloy Solar Cables

Aluminum conductor photovoltaic cables meet TUV 2PfG 2642 and 2954 standards. They use high-quality aluminum alloy materials instead of copper. This change lowers system costs while keeping safety and reliability.

More Products

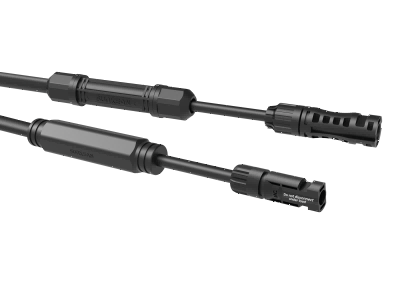

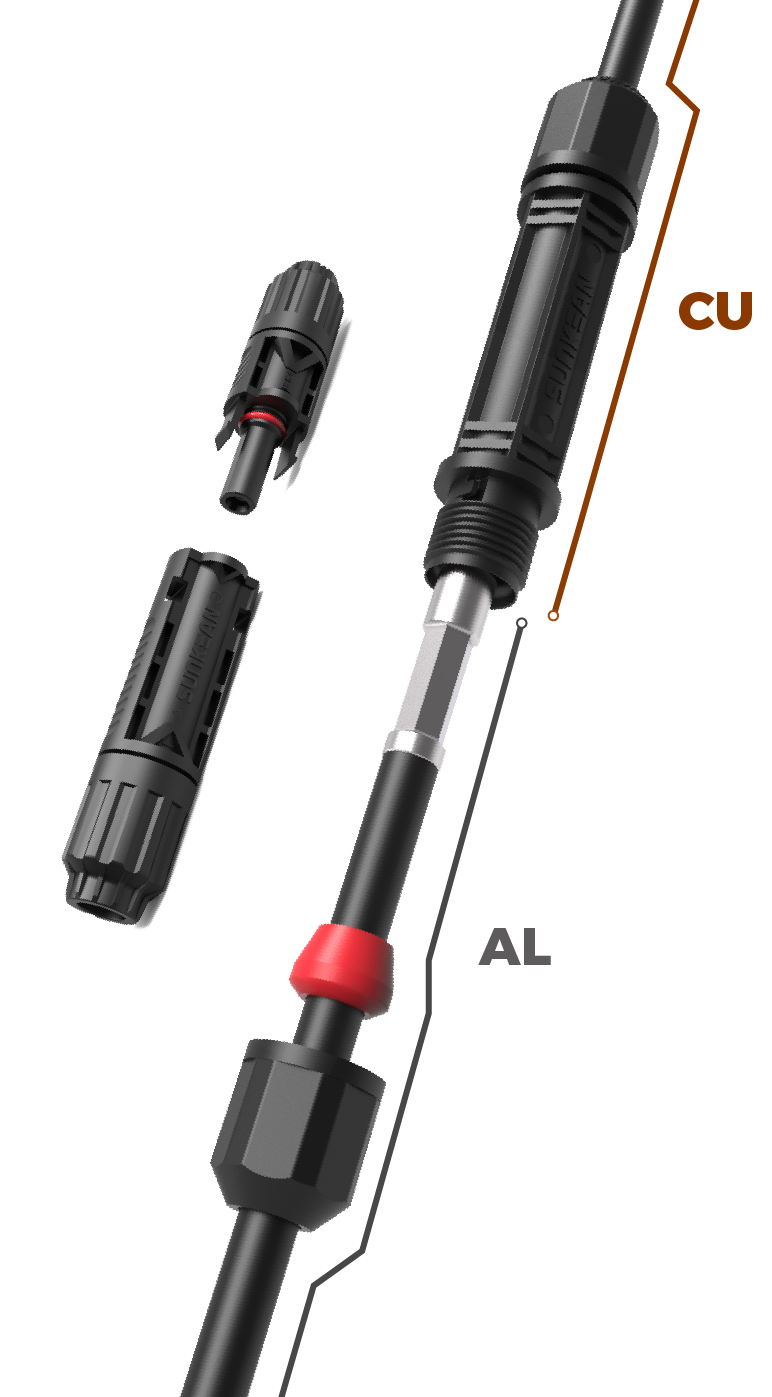

CU-AL Conversion Harness

CU-AL harness can be installed quickly in one minute through self-developed welding technology, reducing costs while improving installation efficiency. In addition, the external quadruple-plating structure can provide maximum corrosion protection, maintain excellent electrical performance in extreme operating environments for 25 years.

Learn More

Economical Cable Connection Solution

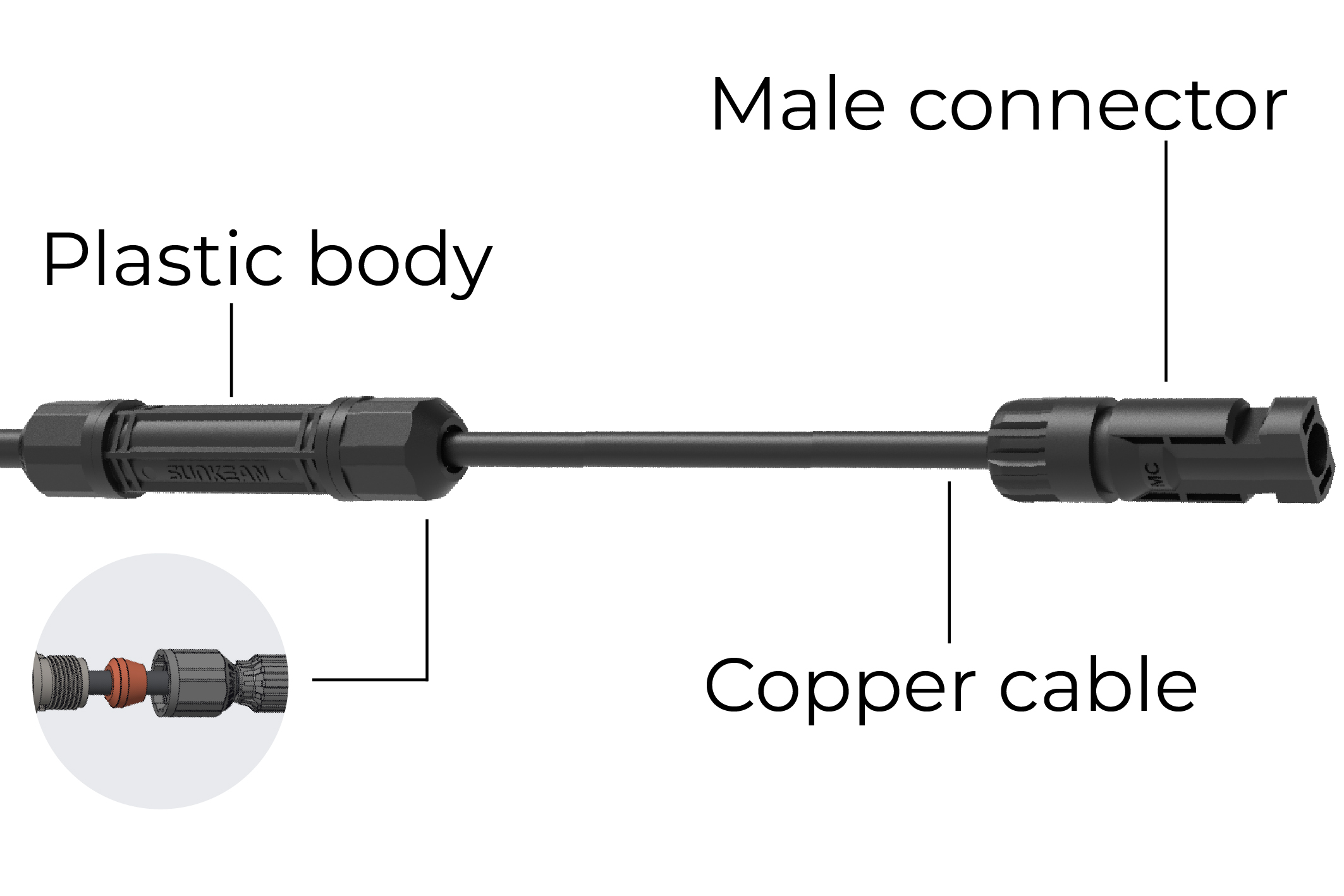

Disassembly of CU-AL Conversion Harness

Pre-assembly of copper and aluminum cables at the female connector end

Remove the dust cover of the aluminum tube and insert the aluminum wire conductor whose length can be flexibly adjusted according to actual needs

Pre-assembly of copper and aluminum cables at the male connector end

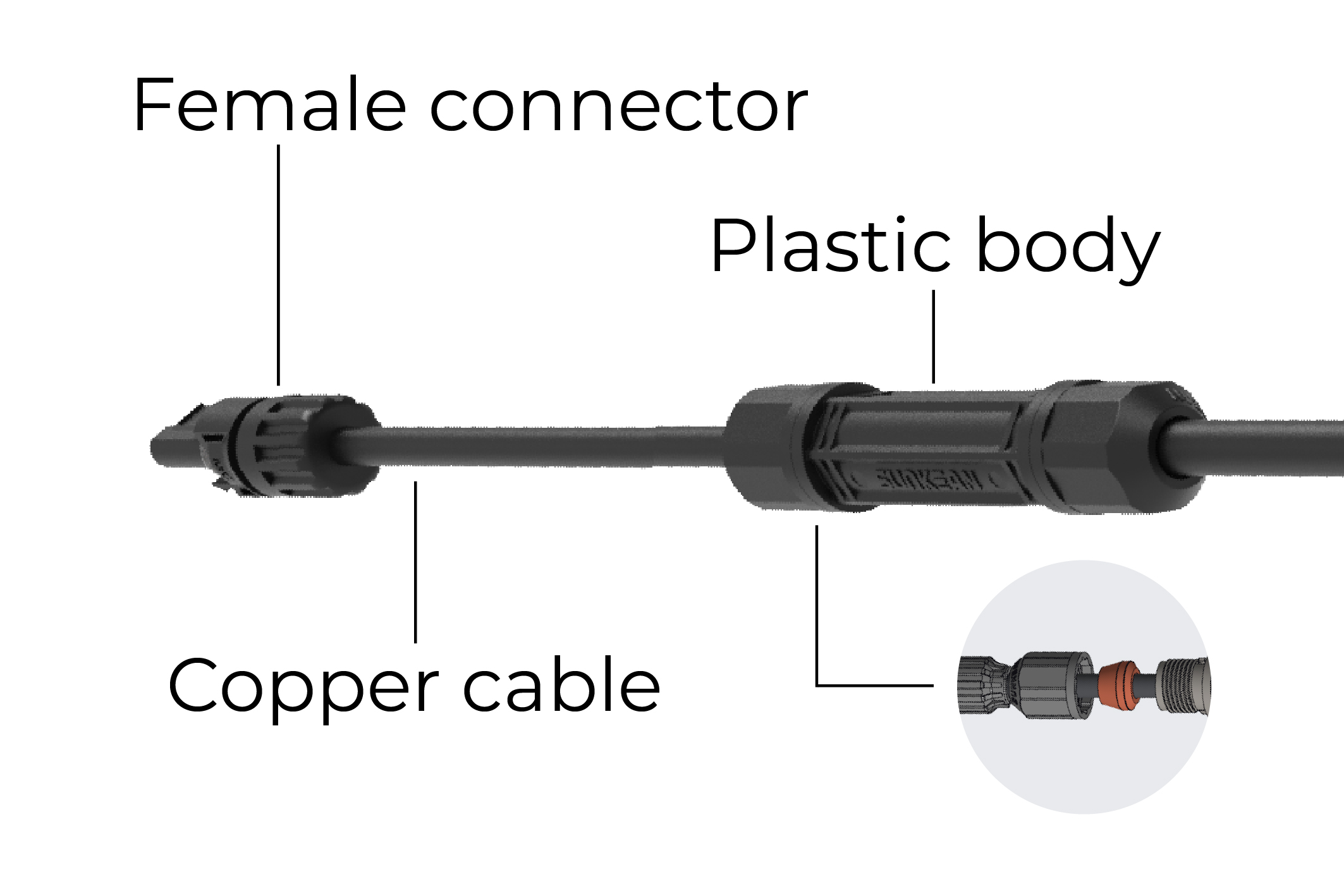

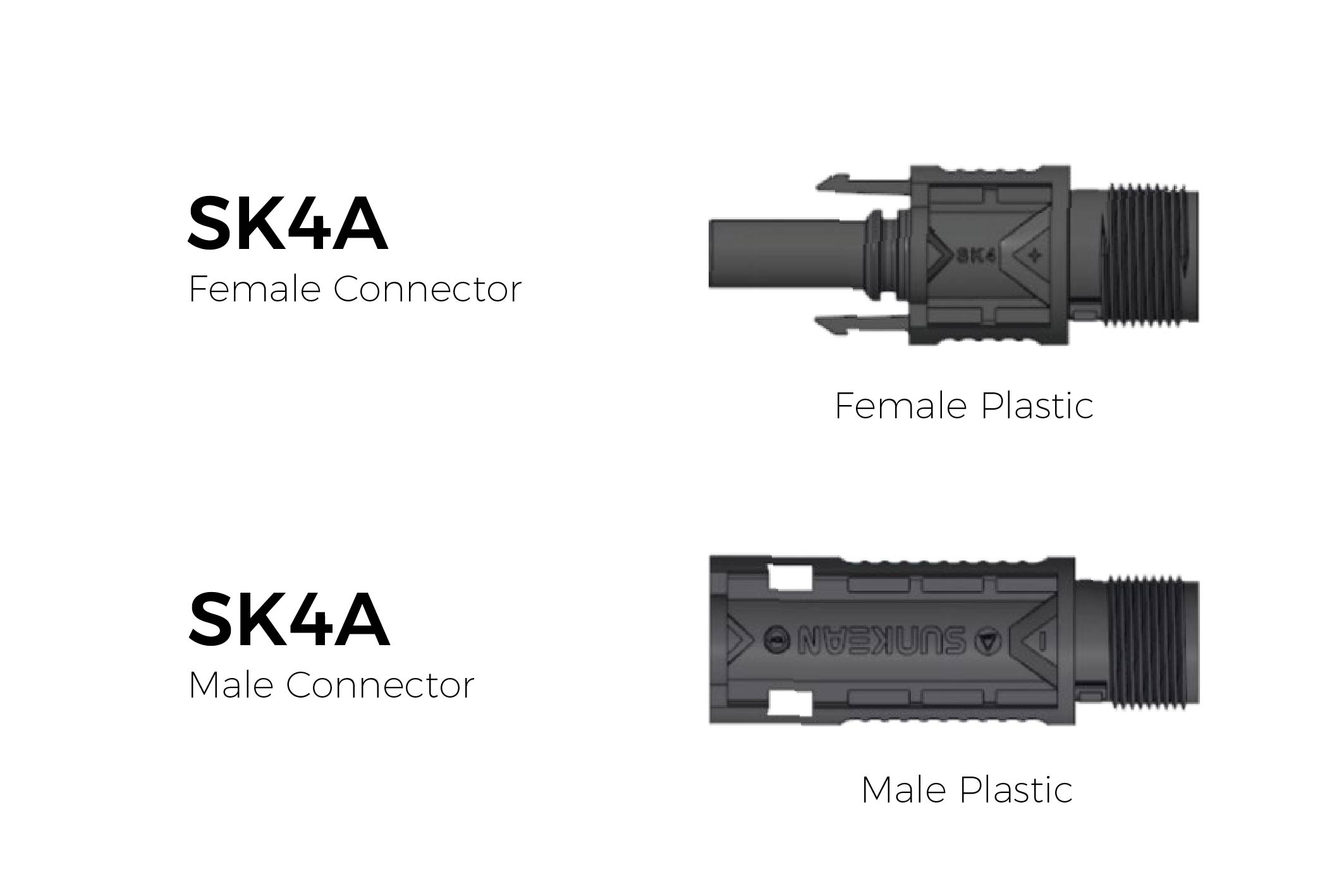

The plastic are made of PA66, a high-performance engineering plastic. The operating temperature is between -40°C and +85°C, with an upper limit of 115°C.

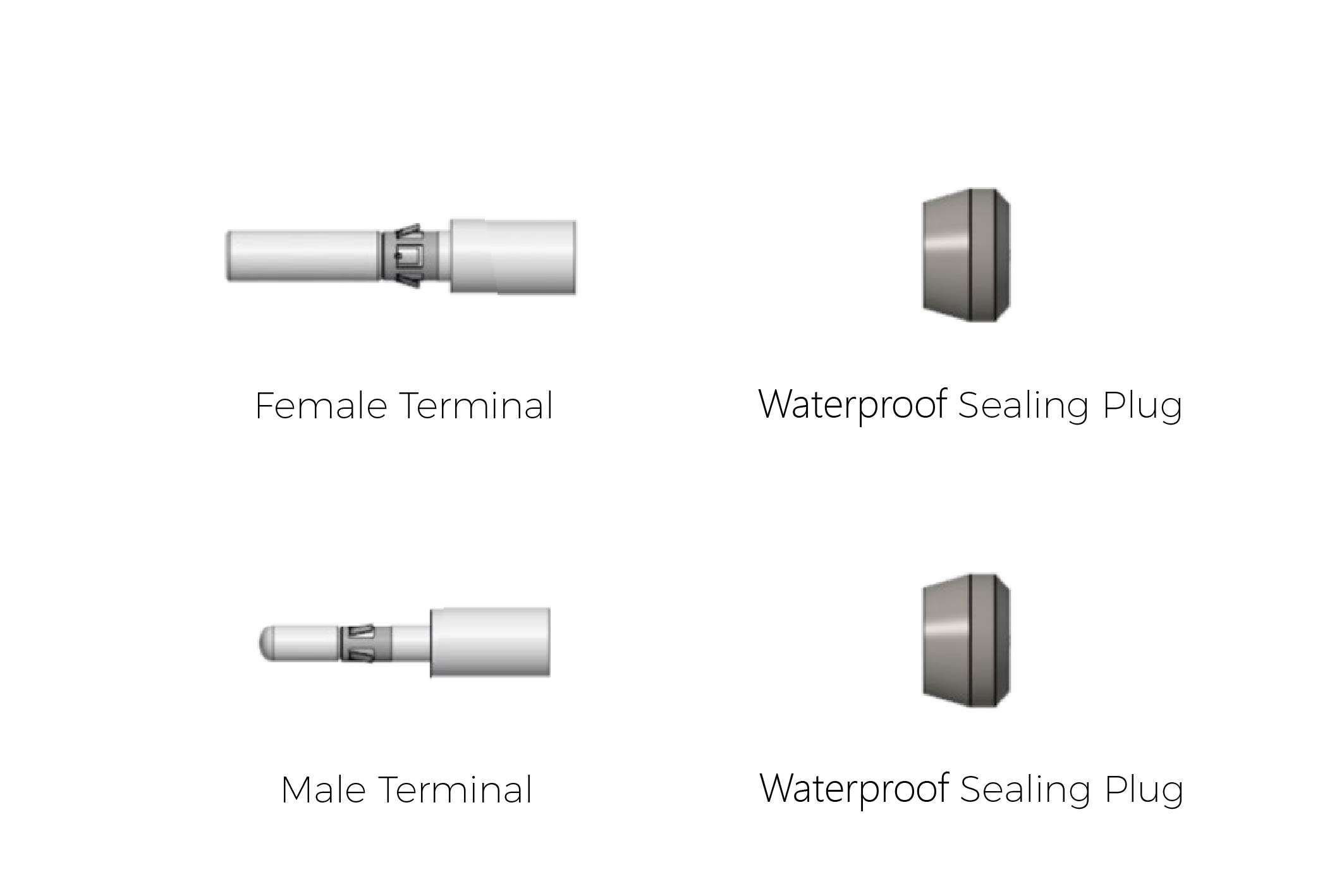

The terminal is made of copper-aluminum alloy, tin-plated, and the waterproof sealing plug is made of silicone rubber.

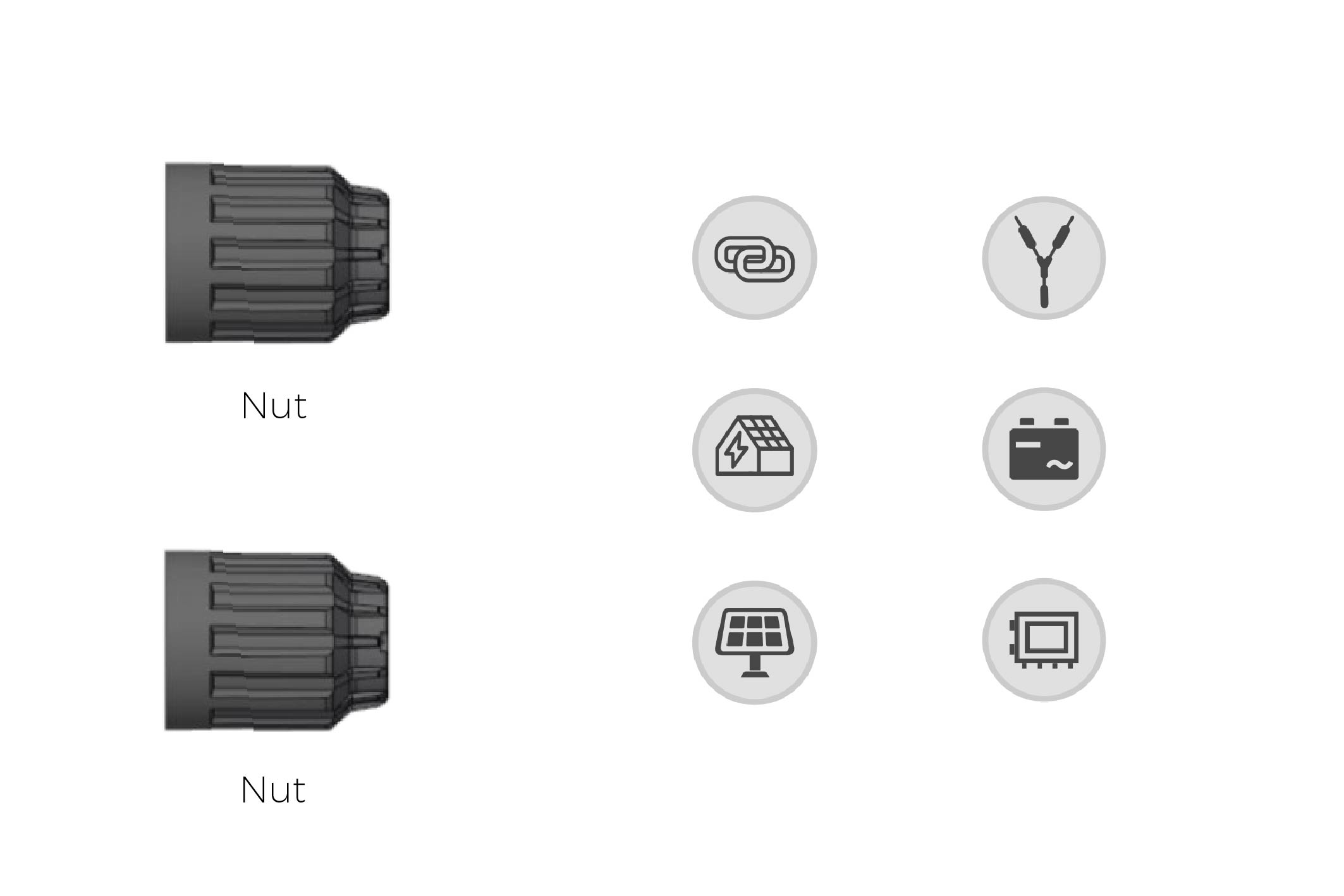

The nut is also made of PA66. SUNKEAN aluminum connectors can be used in copper-aluminum connections, harnesses/branches, power stations, inverters, panels, combiner boxes and other scenarios.

Mature R&D of Aluminum Cable

Why Choose SUNKEAN Aluminum Cable Solutions?

Eliminating Brittle Fracture Risks

The innovative welding process completely avoids the brittle fracture risks associated with traditional fusion welding, while achieving near-zero thermal damage to conductivity, ensuring stable power transmission for over 25 years.

Economical and Efficient

Compared with copper, aluminum has 58% lower cost, abundant resource reserves, and is lighter in weight than the all-copper solution, which can reduce transportation costs.

Superconducting Performance

With TÜV Rheinland and TUV SÜD IEC 62852 dual certification,the specially designed crown spring structure significantly reduces contact resistance and increases current carrying capacity. The annual loss of 1500V system is reduced by 1.2 MWh/MW.

Durable and Corrosion-Resistant

Utilizing a nano-level, four-dimensional gradient coating technology, from inhibiting ion migration at the base layer to resisting extreme environmental corrosion at the surface, ensuring the connector maintains excellent corrosion protection in various harsh conditions and providing 1 year warranty service.

Intelligent Assembly

The quick-plug design reduces installation time to less than 1 minute, and the self-locking mechanism ensures a safe and reliable connection. It has strong compatibility and is compatible with various mainstream connectors like MC4.

Green and Environmentally Friendly

Using a green production process with low energy consumption and zero emissions, 95% of aluminum cable materials can be recycled, reducing carbon emissions over the entire life cycle by 60%-95%.

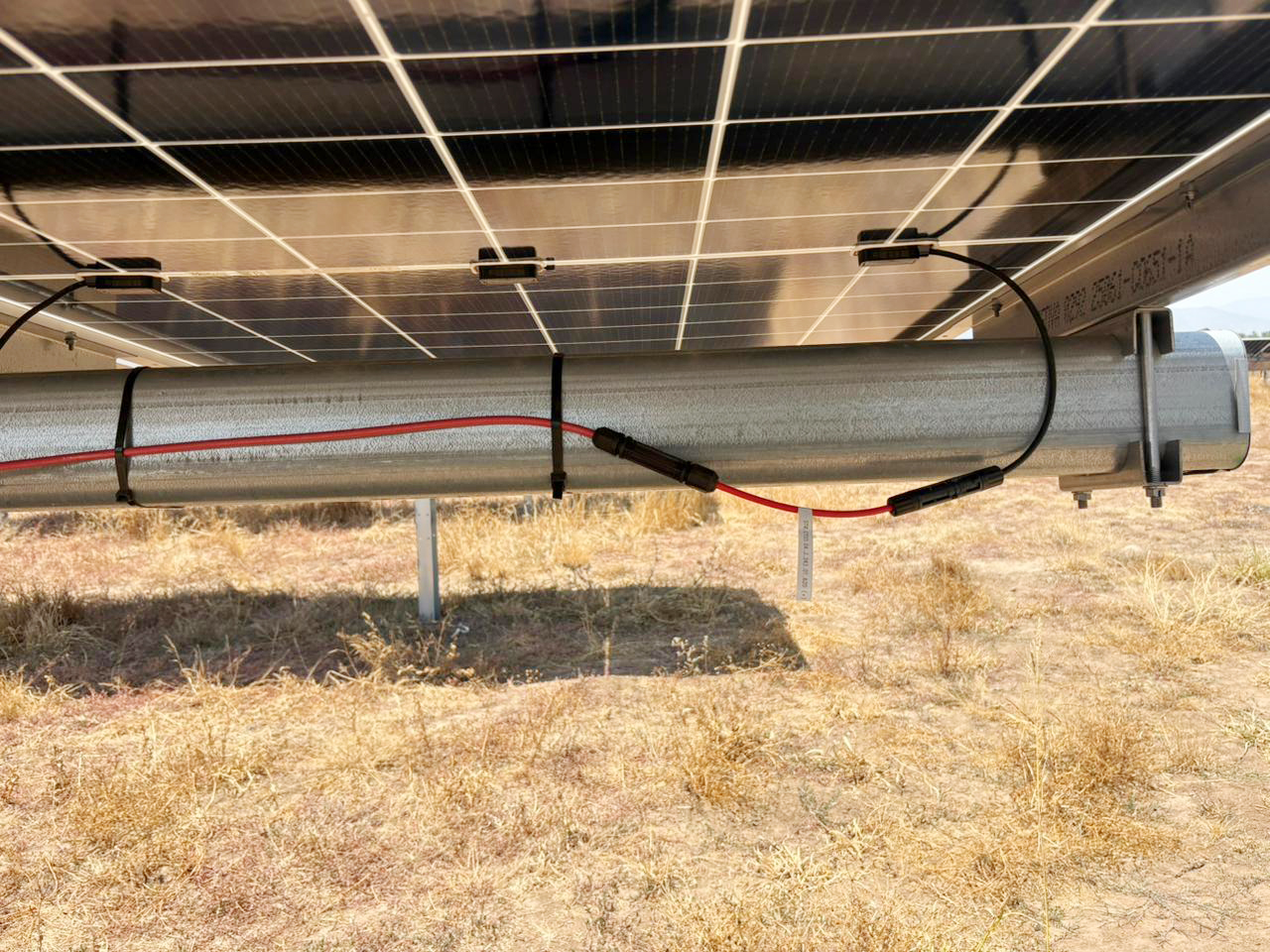

Successful Cases

Trustworthy SunKean

PV Las Violetas

SK-TC Qty: 852 sets

Aluminum Qty: 51KM

PV Los Quilos

SK-TC Qty: 1481 sets

Aluminum Qty: 112KM

Chile Solar Farm

SK-TC Qty: 6000sets

Aluminum Qty: 120KM

Why is aluminum used to replace copper?

FAQ on Aluminum Alloy Cable

How much cost savings can SUNKEAN’s copper-to-aluminum connection solution deliver?

Compared to a full-copper system, this solution reduces costs by up to 58%. In a 1 GW PV power plant project, the savings can exceed USD 2,750,000.

How is SUNKEAN's copper-to-aluminum conversion harness designed to ensure stability and safety?

The harness uses a "copper–aluminum–copper" structure: copper conductors on both ends with an aluminum conductor in the middle, plus a plastic connector housing. It supports high currents and allows quick on-site crimping at the aluminum end for simplified installation.

What welding process is used for the copper-to-aluminum joint, and how reliable is it?

The connection adopts friction welding (solid-state bonding), which operates at low temperatures to minimize thermal damage to the cable. Over 25 years, conductivity degradation is less than 0.5%. The tensile strength is verified through pull and impact testing.

How does the copper-to-aluminum connector maintain corrosion resistance in harsh environments?

The joint surface is protected by a three-layer gradient structure: diffusion layer, chemical nickel plating layer, and hot-dipped tin anti-oxidation layer. An electroplating hole design ensures uniform coating. In a 96-hour 5% salt spray test, no corrosion occurred in the contact area.

Quick Quote

Fill out the form below in 3 minutes to quickly obtain SUNKEAN's customized solutions.

- 1solution

- Phone